“Lakeland Plastics has been a valued partner of our company for 40+ years…They are and have consistently been one of our top tier partners – valued relationship which I would highly recommend pursuing.”

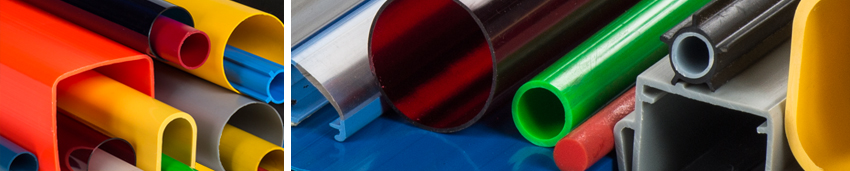

Custom Plastic Extrusions for Designers and Engineers

Custom Plastic Extrusions for Designers and Engineers

Call 1-847-680-1550 Today

to get a quote on your custom extrusion project

At Lakeland Plastics, we specialize in custom plastic extrusion, delivering precise, high-quality solutions tailored to your unique needs.

At Lakeland Plastics, we’ve built our reputation as a leading custom plastics manufacturer by consistently delivering high-quality, precision-engineered solutions. With over six decades of experience, we understand the importance of crafting custom plastic profiles that meet both function and design specifications. Our skilled team works closely with each client to provide tailored solutions that not only meet but exceed expectations. Whether you need a specific shape or profile, our expertise ensures reliable and effective results, every time.

As a premier custom plastic extrusion company, Lakeland Plastics brings unparalleled expertise to the table, offering innovative extrusion solutions for a wide range of industries. Since 1962, our commitment to quality and customer satisfaction has driven our success. With a dedicated focus on custom plastic extrusion, we utilize state-of-the-art technology and a highly skilled workforce to create products that solve challenges and deliver exceptional performance. Whatever your unique needs, we’re ready to bring your project to life with precision and care.

At Lakeland Plastics, our custom plastic extrusion manufacturing process is designed to create high-quality, precise profiles tailored to meet your specific needs. Here’s how we do it:

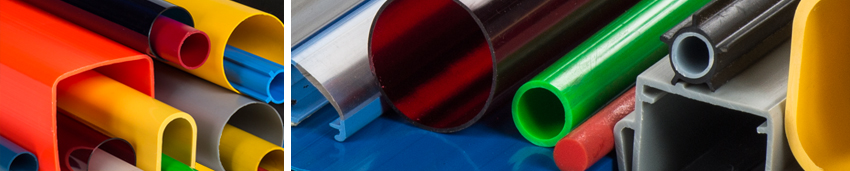

We begin by selecting the right thermoplastic material for your project, choosing from options like high-impact polystyrene, ABS, PVC, polypropylene and more. This ensures durability and the desired performance of your finished product.

Plastic pellets are melted and then forced through a specially designed die. This step turns the molten material into a continuous shape, such as rods, tubes or intricate profiles. The choice of die design allows us to create custom shapes and sizes based on your exact requirements.

Once the material is extruded, it’s cooled and solidified. We can shape it further using techniques like punching, drilling and routering. This is where we turn raw extrusions into usable components for your applications.

For enhanced functionality or aesthetic appeal, we offer co-extrusion and tri-extrusion. This allows us to combine multiple materials or colors into a single product, offering versatility and additional benefits such as added durability or a sleek look.

At Lakeland Plastics, we believe in delivering only the best. Every product goes through strict quality control checks to ensure that it meets our high standards. From prototype trials to large-scale production, we oversee the entire process to guarantee precision and reliability.

Once the extrusions are ready, we provide additional fabrication services in-house, including cutting, assembly and packaging. This allows us to deliver a complete solution that fits seamlessly into your production needs.

“Lakeland Plastics has been a valued partner of our company for 40+ years…They are and have consistently been one of our top tier partners – valued relationship which I would highly recommend pursuing.”

“I have worked with Lakeland for over 25 years… they manufacture quality parts on time every time… I would recommend them to anyone in need of extrusion type products.”

“We’ve had a long-standing partnership with Lakeland Plastics to support building our OTTOLOCK cinch lock bands. Our specifications are not simple and the Lakeland team has consistently demonstrated they are up for the job with a great approach to making the outcome better. We wouldn’t be here without Lakeland and appreciate their mindset in business and customer relationships.”

“Lakeland Plastics is a trusted partner for over 25 years…The reason I like to work with their team is because of the personal attention that they invest into their customers…I know that the job will get done on time and on budget.”

“Lakeland Plastics has been a valued partner of our company for 40+ years…They are and have consistently been one of our top tier partners – valued relationship which I would highly recommend pursuing.”

“I have worked with Lakeland for over 25 years… they manufacture quality parts on time every time… I would recommend them to anyone in need of extrusion type products.”

“We’ve had a long-standing partnership with Lakeland Plastics to support building our OTTOLOCK cinch lock bands. Our specifications are not simple and the Lakeland team has consistently demonstrated they are up for the job with a great approach to making the outcome better. We wouldn’t be here without Lakeland and appreciate their mindset in business and customer relationships.”

“Lakeland Plastics is a trusted partner for over 25 years…The reason I like to work with their team is because of the personal attention that they invest into their customers…I know that the job will get done on time and on budget.”

Whether it’s creating components for machinery or crafting intricate parts for consumer products, the ability to achieve precise dimensions is crucial. One technology that excels in this arena is custom plastic profile extrusion. In this article, we’ll explore the art of custom plastic profile extrusion and how it revolutionizes manufacturing processes by ensuring precise dimensions.…

Introduction Talking about innovation, the process stands out for its remarkable contribution to superior bonding that is Crosshead Extrusion Coating. This revolutionary technique has transformed the landscape of coating applications, ensuring unparalleled durability and resilience across various substrates. Let’s delve into the intricate science behind this marvel of engineering. Unraveling Crosshead Extrusion Coating Crosshead Extrusion…

Introduction The integration of innovative materials plays a pivotal role in enhancing sustainability of green building while maximizing efficiency. One such material making significant strides in this arena is plastic extrusions. These versatile components are reshaping the landscape of construction, offering a plethora of benefits ranging from environmental friendliness to improved performance. This introduction delves…